Beyond Boundaries: Telecom tools facilitate real-time, remote access for manufacturers

The manufacturing sector has been averaging over 10 per cent growth in the past few years. This growth momentum is expected to increase significantly in the future. Moreover, according to a global competitive index study, Asian countries like China and India will emerge as global manufacturing hubs.

The government, keen to give a fillip to the manufacturing industry, has been offering several incentives to international companies to set up a manufacturing base in India. As a result, India is fast emerging as a global manufacturing hub. With an eye on leveraging the opportunities that this growth entails, companies in the manufacturing segment have been increasing their investment in setting up robust communication networks.

As businesses grow, manufacturers have to often contend with huge volumes of data and information that outline the status of individual projects and material requirements, which have to be updated constantly. Such companies need to network their central offices with their worksites, since the sites in most cases are dispersed over a wide area.

According to Kasturi Bhattacharjee, associate director, PricewaterhouseCoopers, “Given that the competitiveness of manufacturing enterprises is now being related to their ability to extract maximum performance from networks, firms are accelerating the implementation of telecommunication solutions. This is being seen as a key strategy to effectively integrate the core activities of procurement, production and distribution, to enable effective collaboration and optimise enterprise productivity.”

Telecom has stepped into this enterprise vertical in a big way. It has helped in monitoring and controlling projects across dispersed centres. It has also simplified the process of supervising projects remotely in real time, with its capability of transferring images, video and data. Telecom networks have also helped companies keep track of the progress of projects by ensuring access to the central information system of the company by retrieving data.

Today, companies in the manufacturing space use a mix of telecom infrastructure, and various other tools and applications to stay connected 24x7. Their communication set-up typically comprises leased line networks, ISDN, Ethernet, VSATs and IP-VPNs.

A company’s major manufacturing centres and main offices are connected through leased lines, owing to the system’s flexibility and ability to save costs. Other regional and area offices and warehouses are connected through MPLS lines, while dealers and service centres are connected via multiple mediums, including MPLS, VSATs and broadband.

Unlike other enterprise verticals such as media, entertainment and government agencies, the manufacturing space utilises managed services extensively. The primary areas of deployment include network services and applications, VOIP, security and data centre services.

Besides these, several other tools and applications are being used in this space. For instance, e-manufacturing is an important tool and the infrastructure deployed comprises web-based technologies that facilitate collaboration between the factory floor and enterprise supply chains. The internet also plays an important role and various web-centric technologies like Java, XML and XML Schema help integrate manufacturing operations with the business enterprise.

Another example of a widespread application in the manufacturing space is computer numerical control (CNC). The application has significantly reduced the number of machining steps that require human action and has helped in enhancing quality and productivity. CNC automation has reduced the frequency of errors and brought in more flexibility in the way components are placed in the manufacturing process and in terms of the time required to change the machine to produce different components. The machines are controlled directly from files created by certain software packages so that the product assembly can go directly from design to manufacturing without the need to produce a blueprint of the manufactured component.

Going forward, Bhattacharjee says that manufacturing majors are likely to continue to invest in telecom tools and infrastructure. Further, she expects several technology trends to emerge in the manufacturing space in the next few years. For example, she believes that industrial automation and control systems, combined with networking products and services, will catch on, as will the radio frequency identification device (RFID). Other likely tools include an industrial wireless video surveillance solution that will provide intelligent video monitoring. She adds, “The evolution of wireless and sensor technologies will permit managers and administrators to gain greater insight into complex processes by securely networking sensor data and transforming it into intelligence throughout the plant.”

According to industry analysts, some of the significant networking components in manufacturing companies in the future will be product life cycle management, RFID, spend management, supplier relationship management, workspace management and messaging services such as IP telephony and information assurance, business continuity and disaster recovery services.

Thus, given the highly competitive environment and complex market dynamics, it is not surprising that manufacturing companies are turning to IT and telecom to enhance productivity and stay ahead of their competitors.

tele.net carried out a survey amongst various companies in the manufacturing sector to assess their telecom requirements and solutions.

The following questions were asked in the survey:

• What are the organisation’s key technology requirements?

• What mix of service providers and vendors is used?

• What are the biggest concerns with respect to telecom infrastructure?

• What are some of the mobility and enterprise applications that the organisation has implemented?

• Which network security tools has the organisation implemented?

• What redundancy tools are being used by the organisation?

• Which new product or service holds the most relevance for the organisation?

Key technology requirements

The survey indicates that telecom plays an important role in the manufacturing space. The respondents state that the use of telecommunications has helped them streamline their supply chain by permitting quick product selection, making adjustments in their pricing strategy, optimising inventory levels and tracking delivery schedules.

Quick and efficient communication also enables manufacturing majors to deploy new strategies as and when market conditions change. Further, remote monitoring provided by effective communication techniques adds value by permitting rapid troubleshooting and on-demand training.

Keeping in mind these functions, most companies use a mix of telecom infrastructure such as EPABX, leased lines, ISDN lines, VSATs, broadband, local area networks (LANs), IPLCs, VPN, Centrex, Ethernet and intercom systems.

Of these, leased lines form the backbone for most of the respondents’ communications set-up. For example, many of Moser Baer India Limited’s (MBIL) offices are connected through 12 MB point-to-point leased lines. This, according to the respondent, affords the company always- on connectivity, which supports bandwidth-hungry applications and helps it trim overheads. For connecting its remote and branch offices, the manufacturing major has opted for an MPLS-VPN set-up owing to its reliability, cost effectiveness and security, and the fact that it was flexible enough to accommodate any required network expansion.

Hindustan Copper Limited (HCL), on the other hand, has opted for an MPLS-based communications set-up. According to Sitendu Dash, senior manager, systems, HCL, “Our 4 Mbps MPLS connectivity, sourced from Reliance Communications (RCOM) is the basic backbone of our telecom set-up. Better quality of service, easy and cost-effective network expansion, flexible bandwidth allocation, network security and redundancy are some of the benefits that the company has gained.”

HCL also uses leased lines. Leased internet lines have helped the company maintain seamless connectivity with its branch offices, according to Dash. The always-on connectivity provided by the medium came at a flat charge, which gave the company an estimate of its communication-related costs.

Vuppalamritha Magnetic Components (VMC) too prefers to use a VPN-based communications network. According to B. Venkatramana, executive director at VMC, “We basically require to connect 26 centres across India. For this purpose, we use a web-based customer relationship management (CRM) application to accept and track customer queries round the clock. This connectivity is achieved via a VPN network, which was chosen as it offers secure access. Also, in order to seamlessly connect to our five manufacturing plants, an optic fibre set-up is used with up to 2.5 Gbps bandwidth.”

Delta Electronics’ telecom set-up is entirely wireline and broadband based. According to the company respondent, “Being a global player, our major technology requirement is to build a high-reliability telecom infrastructure for in-house use and for networking with different offices located in India and worldwide. We focus on using a wireline and broadband set-up, owing to its reliability, low levels of latency and good quality connectivity.”

There are several other applications and platforms used by manufacturing majors. Wynn Telecom Limited (WTL) for instance, uses SAP and CRM applications, both of which are connected to its data centre.

Simmtronics Semiconductors Limited (SSL) also uses a data centre. This performs several functions including ensuring server uptime, data recovery and backup, storage management, hardware and network operations, and end-user and operations support.

MBIL makes use of MS Exchange 2007 servers for messaging purposes while VMC uses GIT, a version control management software, and AutoCAD, a design software.

Sterlite Technologies Limited (STL) is the only respondent that has experimented with and deployed cloud computing. The company shifted all its collaboration-related activities (including email) completely to the cloud. Users can use a suite of cloud-based communication technologies that include email, personal video chat, real-time document sharing, online calendars, personal information portals, etc. All of this takes place on a safe and secure network with the highest form of encryption. Sterlite has also enabled the use of cloud services for its online meetings, training sessions, pre-sales and sales information systems, and for tracking business projects. All of these applications are hosted on a public cloud and are accessible to its employees from across the world.

That apart, STL also uses desktop virtualisation technology. This medium, according to the company, offers several advantages such as making the server administration and management more efficient, and the communications set-up more responsive and agile. STL says that whenever a new server is required, this medium permits it to be provisioned virtually in minutes instead of days or weeks, which may be required in the case of a physical server.

Service providers and vendors

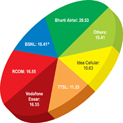

The service providers of choice include Mahanagar Telephone Nigam Limited (MTNL), Bharat Sanchar Nigam Limited (BSNL), Tata Communications, RCOM, Bharti Airtel, Microsoft, IBM, HCL, Pacenet, Hewlett-Packard, Tata Teleservices Limited (TTSL), Vishwaroopa Broadband Services and Hughes.

Issues and concerns

Some of the major issues faced by the companies surveyed are network consolidation, downtime, high costs, redundancies, implementing new software, integration of systems in one place, setting up bandwidth at various locations, customisation of software as per the company’s requirement and ensuring data backup.

For example, the respondent from Delta Electronics says, “Connectivity, consolidation, reducing downtime, uptime, costs and redundancies are really important to us in the same order as this is the real job of the infrastructure team: how to get the best of all worlds and deploy accordingly. For example, connectivity and uptime are closely linked. Cost would not just include the initial deployment cost, but is also related to uptime as loss of work hours due to downtime would add to it. Therefore, we cannot ignore any of these factors at any given point of time.”

According to the respondent from MBIL, ensuring backup for data is a major concern. “Any change or upgrade in our communications set-up impacts our data. So, migrating data to the new infrastructure is a major issue.”

Mobile and enterprise applications

Audio- and video-conferencing, VOIP, instant messaging and webconferencing are popular enterprise applications.

Manufacturing majors are also using enterprise mobility applications. Mobile email, mobile data connectivity, conferencing, personal information management, push alerts, and sales force automation are the most popular tools. For example, VMC provides data connectivity support via USB dongles. These are Tata Photon Plus connections.

Besides these, manufacturing majors also make use of videoconferencing facilities, web servers and mail servers. All of their systems are Windows based and have productivity-related software. Their research and development systems have CAD- and CAM-related software.

Network security

Network security is an important priority for most manufacturing majors. For instance, HCL uses a multi-tiered security infrastructure that comprises Nortel’s intrusion detection system, firewalls, Chekpoint Software, CA antivirus, TrendMicro antivirus and an anti-spam set-up for the company’s mail server and software applications as well.

Redundancy options

While redundancy is very important for these organisations as communications is the mainstay of their business, the majority of the respondents have simple backup options. The most widely used backup options include leased lines, wireless broadband, ISDN lines, UPS backup, tape drive backup, load balance servers, disaster recovery centres, PRI lines, MPLS, mirror servers, disaster recovery set-ups and server provider diversity.

For example, the respondent from Delta Electronics says, “The basic aim is to ensure connectivity at all times. Depending on priority and different geographic locations, our WAN links have redundant leased lines, wireless broadband and ISDN lines.”

Wynn Telecom uses a 3 Mbps line, a 1 Mbps line and a DSL line for backup.

The way forward

Almost all the respondents have plans to upgrade their telecom infrastructure. For example, the respondent from Arvind says the company is looking to implement a new enterprise resource planning (ERP) application. Earlier, the manufacturer had a generic ERP, which was adequate for all functions other than operation-related activities. The new tool is expected to help it improve productivity, eliminate redundant/outlived processes, and rationalise key processes since the solution is very textile centric. In addition, it is aiming to introduce videoconferencing.

SSL has a different view. The respondent says, “While we do have elaborate plans for our telecom set-up, we will be very selective before upgrading any component. We will opt for those mediums that seem tailor-made and suit our requirements the best while being economical.”

Thus, the players in the manufacturing space have realised the benefits of a robust telecom infrastructure and are pulling out all the stops to implement the very best, cutting-edge technology.- Most Viewed

- Most Rated

- Most Shared

- Related Articles

- VMC upgrades its telecom infrastructure

- Beyond Boundaries: Telecom tools facilit...

- Telecom Linked: Manufacturing companies ...

- Revamp Results: Hindustan Copper benefit...

- The Right Steps: UIL’s telecom initiat...

- Telecom Priority: Systems upgrade helps ...

- Telecom Makeover: SSL upgrades its syste...

- Moser Baer adopts a modern, integrated c...

- Spinning Success - Arvind Limited upgr...

- Road to Success - Ashok Leyland derive...

No Most Rated articles exists!!

| Your cart is empty |