Road to Success - Ashok Leyland derives benefits from IT upgrades

-

tele.net takes a look at Ashok Leyland's IT and telecom initiatives...

Legacy system

In the early days, the company's manufacturing units and regional centres had distributed and localised data processing facilities. Data transfer was carried out through tape storage devices, which were physically transported between units as well as between regional marketing offices and the corporate office. The various departments were connected via a local area network. External communication was based mainly on a plain old telephone network.

The shift

Ashok Leyland decided to establish an appropriate IT infrastructure foundation to bring in efficiency and speed through optimised workflow. It drew up a multiplepoint agenda, with the aim of replacing the relatively dated network and communication systems with state-of-the-art technology to ensure secure communication between its production units, countrywide offices and channel partners.

A combination of technologies was employed based on business needs and criticality to get an optimal cost-benefit ratio. Built-in fallback operations were part of the company's plan to minimise loss of productivity and focus on business continuity.

Keeping these requirements in mind, the company opted for network components such as DLC (local loop); DLC (NLD); ISDN; VSATs; ATM/frame relay; point-to-point Ethernet and MPLS. Such WAN technologies were deployed for connectivity between the manufacturing major's plants, area and regional offices, warehouses, stockyards, etc.

To enable this integrated computing and communications infrastructure, Ashok Leyland has established a centralised data centre facility in Chennai and a disaster recovery centre at Hosur. Its manufacturing units and main offices are connected to data centres through leased lines. The company's other regional and area offices and warehouses are connected through MPLS lines. Its dealers and service centres are connected via multiple communication links such as MPLS, VSATs and broadband.The company employs bandwidth ranging from 2 Mbps to 6 Mbps over its leased lines. Its primary data centre and the disaster recovery centre are connected via a large pipe to accommodate its data replication needs, covering a host of business services such as ERP, mail, dealer systems and supplier systems. The MPLS lines' bandwidth ranges from 64 kbps to 1 Mbps. The VSATs use both PAMA and FTDMA technologies provided by HCL Comnet.

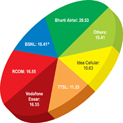

The automobile major uses the services of BSNL and RCOM as the primary and secondary service providers for connectivity, thus ensuring fail-safe operations at the service provider level. For last mile connectivity, the company predominantly uses optic fibre and copper cables, while wireless connectivity through radio frequency is used in some difficult terrain.

The company also makes use of several mobility applications. For example, mobile email is extensively used; senior executives use BlackBerry smartphones to access their mail. Video conferencing through the WAN/internet is another popular connectivity option.

The company has implemented critical business applications such as enterprise resource planning (ERP), a centralised dealer management system, a supplier collaboration portal, an incentive coupon redemption application for parts retailers and mechanics, etc. For data and network security, it has employed user authentication, intrusion detection and prevention systems, and OS security patches.

Challenges and benefits

The company encountered a few challenges while installing the new system. Building data centres that are 27001 certified as well as procurement and commissioning of data centre infrastructure such as servers and storage were not simple tasks. Similarly, setting up WAN links, building and testing centralised business applications, commissioning them and ensuring business continuity were a challenge.

However, the business and operational benefits far outweigh the challenges and substantial investments the company has made while upgrading its infrastructure. It has witnessed significant improvement in business process execution. The centralised applications and availability of data on a single, integrated platform have also aided analysis and business decisions.

The company is able to conduct its business in a uniform manner through the use of centrally deployed servers and storage media, which ensure fail-safe operation.There is also adequate built-in redundancy which ensures there is "no single point of failure". Thus, there is real-time data availability with integrity and security.

Moreover, the IT-enabled development and production systems are centrally managed and the entire business operations and services are monitored centrally. Proactive resource and capacity planning has become easier.

Going forward, the company plans to migrate from home-grown software and move to an ERP platform, which will help it meet the increasing demands of its various ventures and lines of business.

- Most Viewed

- Most Rated

- Most Shared

- Related Articles

- VMC upgrades its telecom infrastructure

- Beyond Boundaries: Telecom tools facilit...

- Telecom Linked: Manufacturing companies ...

- Revamp Results: Hindustan Copper benefit...

- The Right Steps: UIL’s telecom initiat...

- Telecom Priority: Systems upgrade helps ...

- Telecom Makeover: SSL upgrades its syste...

- Moser Baer adopts a modern, integrated c...

- Spinning Success - Arvind Limited upgr...

- Road to Success - Ashok Leyland derive...

No Most Rated articles exists!!

| Your cart is empty |