Domestic Drive: Government push needed for indigenous equipment manufacturing

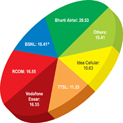

The Indian communication sector has been registering phenomenal growth but the same cannot be said of the domestic manufacturing base for telecom equipment. The success witnessed by home-bred players like Bharti Airtel, Idea Cellular and Reliance Communications (RCOM) in the services sector has eluded their counterparts in the manufacturing industry. As per market estimates, the Indian market for core equipment (excluding batteries and towers) is estimated at Rs 250 billion, of which the contribution of local firms is limited to Rs 10 billion. In addition, the Indian telecom industry’s spend on telecom equipment (excluding handsets) is expected to stand at Rs 460 billion in 2014-15, with the majority of this amount directed towards sourcing equipment from markets like Europe and China. In fact, given the increasing consumption of electronic goods in general and telecom equipment in particular, it is expected that the country’s import bills for electronic products will surpass its fuel bill in a few years.

An underdeveloped manufacturing ecosystem, inadequate support infrastructure (poor grid availability, logistics issues and high finance costs), and limited support and incentives from the government have affected the growth plans of domestic manufacturers. As a result, private operators have continued to rely heavily on imports for meeting demand.

Unprecedented growth in the country’s wireless segment has led international manufacturers like Alcatel Lucent, Ericsson, Huawei, Nokia Networks and ZTE to set up manufacturing units in India. However, the value addition attributable to India remains low as these manufacturers have foreign intellectual property rights (IPR). As per industry reports, the value added in India is less than 11 per cent at present, implying that the import content continues to be significantly high.

In such a scenario, the government’s policy support becomes crucial for giving an impetus to indigenous manufacturing, which will result in reduced import bills as well as an enhanced technical production base in India. Over the past few years, the Ministry of Communications and Information Technology and the Department of Electronics and IT have come up with several policy initiatives in this regard. The National Telecom Policy (NTP), 2012; the preferential market access (PMA) norms; the National Policy on Electronics, 2012; and the Electronic Modified Special Incentive Package Scheme have the potential to make India a major telecom equipment manufacturing hub in the next few years. However, there has been a lack of vision and effort towards the implementation of these policies.

Another factor to be considered is the failure of domestic manufacturers like ITI Limited, Tejas Networks, Kavveri and Sterlite to be at the centre of the Indian telecom sector’s transition from 2G to 3G and 4G. Their contribution has largely been limited to the tenders floated by state-run Bharat Sanchar Nigam Limited (BSNL), Mahanagar Telephone Nigam Limited, RailTel and Power Grid Corporation of India Limited.

tele.net takes a look at the key hurdles facing domestic manufacturers, as well as the expectations from the government…

Stiff competition from international vendors

Global telecom equipment manufacturing companies, which are headquartered in developed telecom markets, have been better prepared and more adequately equipped than their Indian counterparts to participate in India’s 3G/4G revolution and the upgrading of the country’s network. They have established a strong manufacturing base in India during the past decade, but their value addition continues to be low. This is because no foreign company is ready to give its IPR to Indian companies despite having a huge employee base in the country. Their scope of work in India is limited to system integration and packaging, while the design and IPR aspects, which constitute a big part of value addition in the segment, continue to come from outside India. For instance, on an average, only a fourth of the value of the equipment sold in India by Chinese manufacturers is reportedly developed locally.

Sourcing equipment from Chinese vendors has facilitated easy financing for operators. Chinese banks provide huge credit lines for companies buying their country’s equipment. For instance, in 2011, RCOM signed a $1.3 billion loan agreement with the China Development Bank. This was the largest loan deal between the two countries at the time, and it was supplemented with a $600 million agreement for financing telecom equipment imports from Chinese vendors.

Typically, Chinese banks offer credit at 2 per cent interest, which is payable over 15-20 years. Thus, favouring Chinese operators against domestic manufacturers makes perfect business sense for service providers operating in India’s hypercompetitive telecom market.

Regulatory bottlenecks

Complex tax laws and the complicated process of obtaining regulatory approvals are the major factors impacting investor sentiment adversely. For instance, the recent tax dispute involving Nokia’s handset manufacturing factory in Chennai has resulted in the state-of-the-art facility lying stranded. It was not even transferred to Microsoft when the global giant acquired Nokia’s handset business. Nokia, though, does not need the factory as it has opted out of the handset business and is keen on selling it to a local handset manufacturer. This could give a push to the overall Indian handset manufacturing system but the tax settlement is taking too long and the facility is lying unused during the process.

High costs

Indian manufacturers face a significant cost disadvantage as compared to foreign companies that import equipment. As per a study conducted earlier in the year by the India Electronics and Semiconductor Association and Ernst & Young, the domestic telecom industry faces a fiscal disability of up to 26 per cent as compared to foreign companies. Finished telecom equipment can be imported at zero duty, but components have duty ranging from 10 per cent to 15 per cent. Indian telecom equipment-makers pay 16-18 per cent interest on loans, and infrastructure costs like those of power are higher here as well. Unlike foreign players, Indian firms do not get any research and development (R&D) incentives or soft loans for product development.

Policy limits

The scope of the PMA policy is limited to government contracts and does not extend to private telecom operators or global telecom network vendors. Even in that limited area, it is yet to be strictly enforced. Government orders that require local sourcing of equipment often have restrictive eligibility conditions, such as the need for a proven track record as well as strict net worth rules. These clauses prevent local manufacturers from bidding for such contracts. For instance, BSNL recently floated a tender for routers to cater to the Rs 150 billion Network for Spectrum project with the condition that the manufacturer should have deployed a substantial number of similar products in the country. No Indian manufacturer could fulfil this requirement.

Industry expectations

Government support is crucial if domestic telecom manufacturers are to be on a level playing field. To this end, the government needs to look at the rationalisation of taxes, tax incentives and the development of integrated infrastructure. Incentives such as a 10-year income tax holiday, excise waivers and low-cost bank loans can be considered. At present, 10 per cent excise duty is levied on domestic telecom equipment producers that are not located in special economic zones.

The government has also finalised a blueprint for setting up three specific funds with a combined corpus of Rs 175 billion. This is intended to help the telecom sector develop a strong domestic manufacturing base, encourage entrepreneurship, and promote R&D. These funds will provide start-up and angel funding, finance incubation centres, and offer soft loans, apart from giving interest subsidy to banks lending to telecom companies. The government must also seriously look at and approve the proposals for funding R&D and IPR-driven domestic products through the Telecom R&D Fund under the NTP, 2012.

Overcoming infrastructure bottlenecks like right-of-way issues is important to ensure expeditious fibre roll-out and the future-proofing of telecom networks. The industry is also hoping for successful conclusion of the upcoming spectrum auctions, which will see operators making long-term investments in upgrading their networks to support advanced technologies.

Government-driven projects like the National Knowledge Network and the National Optical Fibre Network have already opened up new vistas of opportunities for domestic equipment manufacturers, with the related tenders favouring local vendors. State-owned RailTel and Powergrid have also included local sourcing in their contracts. The government intends that by 2019-20, only 20 per cent of the country’s telecom equipment should be imported.

Going forward, the industry has high hopes from the new government’s Make in India campaign as well. Its objective is to build an ecosystem conducive to equipment manufacturing and revive domestic equipment manufacturing.

If implemented properly, government policies supporting local manufacturing can prove to be a game changer for indigenous telecom equipment manufacturers.

- Most Viewed

- Most Rated

- Most Shared

- Related Articles

- Manufacturing Hub: India emerges as a ke...

- TRAI performance indicator report for Se...

- Prashant Singhal, partner, telecom indus...

- 2G spectrum scam: continuing controversy

- An Eventful Year: Telecom highlights of ...

- Telecom Round Table: TRAI’s spectrum p...

- Manufacturing Hub: TRAI recommends indig...

- Linking Up: ITIL to merge with Ascend

- High Speed VAS - Killer applications w...

- Bharti Airtel seals deal with Zain - Zai...