Cable Connect: RF feeder market picks up with network rollouts

The most common type of antenna feeder cable used in a telecom tower is the radio frequency (RF) cable. Also referred to as the coaxial feeder or coax cable, the RF cable is an electrical cable with an inner conductor surrounded by a flexible tubular insulating layer, surrounded by a tubular conducting shield. The term coaxial comes from the inner conductor and the outer shield that share the same geometric axis.

The RF cable is used to transfer radio frequency energy from one point to another. Thus, it is used as a transmission line for radio frequency signals in applications such as feedlines connecting radio transmitters and receivers with their antennas, computer network (internet) connections and distributing cable television signals.

RF coaxial connectors, cabling and signal transmission systems find extensive applications in cellular infrastructure as well as in cabinet solutions inside base stations, controllers and antenna systems. In mobile towers, feeders are used as a transmission medium to carry high frequency or high broadband signals between an antenna and its base station.

The RF products market can be segmented into connectors (including jumper assemblies) and cables. The RF and feeder cables are mainly of four categories – 7/8 inch, 1/2 inch, 1/4 inch and 1-5/8 inch cables. Of these, the 7/8 inch cable category accounts for close to 90 per cent of the total market share. The other three categories account for the remaining 10 per cent, with the 1/2 inch cable in the lead.

Market dynamics

Feeder cables constitute a very small part of the active infrastructure, which also includes spectrum, base transceiver stations (BTSs), switches, antennas, etc. Although these cables are used for connecting the BTS to the antennas, with the large number of BTS stations in the country, the total size of the RF feeder cable industry becomes quite large. As a thumb rule, about 300 metres of feeder cable is used in a telecom tower. In today’s competitive market, where infrastructure sharing is crucial and towers are shared by many service providers, the feeder cable requirement is 300 multiplied by the number of service providers sharing a tower. In addition to feeder cables, jumper cables of 1.5 metres are also used at the cell sites. With over 580,000 BTSs operational in the country, the Indian RF feeder cable industry currently has over 170 million metres of cables and about 840,000 metres of jumper cables.

The current cable market size is estimated at around $180 million. In terms of cable length, the domestic market size for RF cables is about 70,000 km per annum. While the installed capacity for cables in India is about 40,000 km per annum, the balance is met through trade imports from countries like China and South Korea.

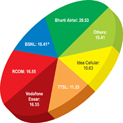

While the key players in the Indian telecom cable market are Commscope (formerly Andrew Wireless), Shilpi Cables, LS Cables and Microqual Techno Limited, there are other smaller players too like Huber and Sunher, Kavveri Telecom Products Limited, Radiall, RFS, Rosenberger and TVS Interconnect Systems. Commscope dominates the RF feeder cable market with a share of over 50 per cent.

Growth drivers

While the RF feeder cable market has so far been driven by a strong growth in 2G mobile telephony services across the country, the key factors that will impact its growth in the future include 3G and broadband wireless access (BWA) network rollouts and expansion into rural areas.

A strong subscriber base and healthy growth estimates based on the expansion of mobile telephony in rural India are expected to be the key drivers for the telecom cable industry. Of the total 826 million subscribers as of April 2011, over one-third live in rural areas. Moreover, with urban teledensity at over 80 per cent, the monthly growth in rural subscriber base (2.18 per cent) has been much higher than its urban counterpart (1.74 per cent). Industry experts estimate that about 150,000 cell sites will be added to the existing telecom infrastructure by 2012, most of which will be located in remote regions.

The rollout of 3G and BWA networks, which require high frequency low-loss cables, will also be a key factor in driving the demand for these cables. Of the nine operators that have the spectrum to offer these services, eight have already launched 3G services. However, coverage has been limited so far with most of it being concentrated in urban areas. “3G will have a positive impact on the industry but so far it has not achieved the numbers one would have expected. The rollouts have been a bit slower than anticipated,” says Pankaj Gandhi, director, wireless sales, India and SAARC, Commscope.

The entry of six new operators in the sector has also impacted the telecom cable industry, especially when active infrastructure sharing as a concept has not caught up in India so far. However, among all these, only Uninor and MTS have rolled out the most extensive networks vis-à-vis others such as S Tel, Etisalat DB, Videocon and Loop Mobile.

Another new yet effective concept, in-building solutions (IBS) is likely to be a positive catalyst in the growth of RF feeder cables in India. In the IBS system, a BTS of a smaller scale is deployed to serve a localised subscriber base, resulting in a tremendous improvement in the quality of service (QoS). Though the concept has only been tested in pilot projects in the country, it is expected to gain traction as the competition stiffens.

Given that incumbents like Bharti airtel, Vodafone Essar and Bharat Sanchar Nigam Limited have been in operation for over 15 years, some of their telecom infrastructure is due for replacement or upgradation. This is also likely to create an additional demand for RF cables.

Key trends

The telecom industry is witnessing the adoption of a new concept, that of split radio architecture, which envisages a shift from a centralised RF architecture to a distributed one, which uses remote radio heads (RRHs). On the positive side, this will help operators minimise the footprint of their installed base station equipment. It will also help reduce RF losses along cables when distributed remote radio elements are placed close to the antennas. On the downside, this could impact the demand for RF cables, as the new architecture reduces the need for feeder cables.

However, industry experts believe that this is not likely to affect the RF feeder market in India adversely, as it is not always possible to install the RRH close to antennas because of the lack of space in increasingly shared towers or rooftops. “Its uptake has not picked up significantly so far. In the Indian context, it does not seem very feasible, as existing towers are crowded and the design is such that there is no extra space to install an RRH at the tower. Therefore, it is more of an installation issue,” says Gandhi.

Moreover, even in a distributed RF set-up, when RRHs are close to the antennas, jumper cables would still be needed. Even when RRHs are positioned on rooftops (rather than towers), the site configuration often makes it necessary to use longer RF jumper cables (10-15 metres being the common practice).

The RF feeder cable industry has been constantly evolving in terms of cable design. New innovations like Commscope’s smooth wall aluminium cable, which not only offers reduced signal losses but is also cheaper than the traditional RF cable, have been well received in the industry. Other variants like foam-filled cables and hybrid cables signify the dynamic nature of the market.

The traditional RF cable is made of copper. However, driven by factors like fluctuating copper prices and the cost-sensitive nature of the telecom industry, cable manufacturers have been moving towards aluminium as the primary raw material for cables. The use of aluminium not only provides stability to the fluctuating prices but is also cheaper than the standard copper cable.

Issues and challenges

In view of the extreme volatility of copper prices in recent times, aluminium has emerged as an important substitute for copper, as it provides a stable price to customers over a longer time frame. With the price ratio of copper to aluminium having crossed the 5:2 mark in 2010, this issue becomes more critical and impacts the operators’ medium- and long-term strategies as well as planned expenditures. But even now, the industry uses a significant amount of traditional copper cable.

There continue to be frequent reports of cable theft, with cables being stolen for the scrap value of their metal content. Though cable theft has existed as a low-level problem for many years, it is now becoming a serious issue given the rise in metal prices, especially copper.

With the growing volatility in input costs and increased demand for improved efficiency, the RF feeder cable industry is constantly changing. Regular innovations in the product segment have helped telecom operators reduce signal losses and improve their QoS. The future of the industry will be about product innovations, and will be driven by the huge rural market that still needs to be tapped.

According to industry experts, the RF cable market is expected to peak at $225 million by 2012 because the industry is directly dependent on the network rollout by operators, which is expected to decline from 2014 onwards. By that time, most operators should also be through with their respective 3G network rollouts.

- Most Viewed

- Most Rated

- Most Shared

- Related Articles

- Demand Drivers: Government schemes and d...

- Advantage OFC: Fibre cables emerge as a ...

- Cable Connect: RF feeder market picks up...

- Cable Market Trends: OFC emerges as the ...

- On a High Frequency: Increasing RF deplo...

- Demand for Cables: Issues and opportunit...

- Cable Connect: Submarine network industr...

- Chequered Growth: Issues and challenges ...

- Global Connect: Key trends and challenge...

- OFC Focus: Government initiatives to exp...

No Most Rated articles exists!!