Enhancing Networks: SCCL leverages telecom to enhance operational efficiency

Singareni Collieries Company Limited (SCCL) is jointly owned by the Andhra Pradesh government and the union government on a 51:49 equity basis. The Singareni coal reserves stretch across 350 km of the Pranahita-Godavari valley in Andhra Pradesh and have proven reserves aggregating 8,791 million tonnes (mt). SCCL currently operates 13 open cast and 42 underground mines in four districts of Andhra Pradesh. The company produces over 50 mt of coal annually and has a workforce of approximately 67,000.

With the aim of streamlining operations and improving network connectivity, SCCL recognised the need for an upgraded, top-of-the-line communication infrastructure. It opted for a multi-tiered information technology (IT) and telecom set up that would provide robust connectivity and reduce downtime.

tele.net tracks the development of SCCL’s IT and telecom set up...

Legacy system

According to Geeta Mohan, deputy general manager, IT, “Computerisation at SCCL goes back nearly three decades. In the initial days, processes such as the employees’ payroll, material management and financial accounting were automated. The automation process took place in a distributed manner for nearly two decades.”

The shift

The full automation of business processes took place in a phased manner. As computer usage increased in the company, a large number of computers were installed at the corporate office. These systems were connected by establishing a local area network (LAN) at the corporate office in 1998. The next step was the introduction of basic applications like CAD that helped in mine planning. This began in the 1990s.

SCCL next introduced a mine management system, following which computers began to be used at the unit level. A LAN was set up at each unit to connect these systems.

A number of software applications were installed at the company’s mines and various departments. The scope of these applications was increased from only finance-centric functions to include purchase and material management. The company also took measures to upgrade its infrastructure to meet its growing technology requirements.

In early 2000, the company decided to implement SAP. Thus, steps were taken to upgrade its existing infrastructure to accommodate SAP, and a suitable network was established in all 10 functional areas and at SCCL’s nearly 130 sub-units and mines.

Optic fibre cables and wireless technologies were introduced for last mile connectivity. According to Mohan, this technology combination proved to be the most cost effective, besides accommodating the heterogeneous nature of the network.

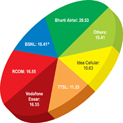

Currently, 10 functional areas and the company’s corporate office at Kothagudem in Khammam district are connected to its data centre in Hyderabad through a 2 Mbps leased line connection sourced from Bharat Sanchar Nigam Limited. Inter-area connectivity has been established through various wireless connectivity mediums to provide redundancy using equipment sourced from RADWIN.

SCCL’s coal dispatch points have been provided VSAT connectivity to ensure business continuity at the selling points. All functional units have broadband connectivity as back-up, in case the leased line set-up fails. Also, alternative mediums of connectivity have been sourced from RailTel to ensure uninterrupted connectivity to SCCL’s data centre at Hyderabad.

Wide area network (WAN) connectivity has been established using Cisco products and a 9 Mbps internet connection sourced from Tata Communications. RailTel products are being used at the company’s data centre. A 1 Mbps broadband connection is available as well.

Mobile users now use secured VPN connectivity to stay connected to the company’s network while travelling. A videoconferencing facility is provided at three locations in the company, while web-based videoconferencing from desktops is being used as a communication medium.

SCCL’s entire connectivity set-up has been designed by its in-house team. However, the installations have been outsourced, as has the material required for installation of the network. The established network is being used by nearly 14,000 employees.

Benefits and challenges

Establishing such a huge network was, no doubt, quite a challenging task, not only because of the company’s geographical spread but also due to the location of certain units in difficult terrain such as in forest areas. “Not many service providers have a proper infrastructure set-up in such areas,” says Mohan. “Proper wireless signals are not available, as the line of sight is not present on account of overburden dumps created as a result of mining activity. Moreover, ensuring stable power supply is a challenge as fluctuations are very frequent due to the use of heavy mine machinery.”

The current set-up and implementation of SAP have helped the company achieve real-time updation of the available coal stocks. Moreover, the company’s business processes are now completely transparent.

Going forward, SCCL plans to enhance its redundancy level. “At present, redundancy is provided only for major functional areas. We plan to provide redundancy to all functional units, improve connectivity at the unit level and improve network security in the next phase,” Mohan says.

All in all, SCCL has realised the benefits of an enhanced telecommunications network in consolidating its leadership position in the Indian mining industry and improving its day-to-day functioning

- Most Viewed

- Most Rated

- Most Shared

- Related Articles

- Keeping Track: Logistics companies lever...

- Telecom Take-off: DIAL uses communicatio...

- Smooth Sailing: Port of Visakhapatnam st...

- Telecom Gains: Sobha Developers upgrades...

- Delivering Value: Logistics companies le...

- Power of Telecom: MPPKVVCL improves oper...

- On the Move: Logistics companies keep ab...

- Telecom Track: Indian Railways makes its...

- Data Warehousing: ALL revamps its commun...

- A Secure Network: MTIL migrates to an ad...